An automotive parts supplier needed an in-process monitoring system for high volume deburring of small parts using electrochemical machining (ECM).

The company discovered their ECM process was not 100% reliable, leading to parts being quarantined by their customer, and extremely time consuming manual inspection under a microscope for all parts.

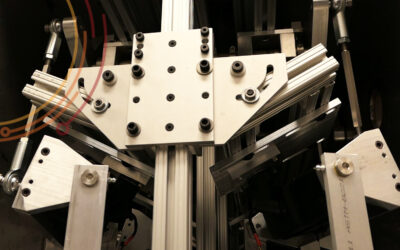

SIS developed a method to monitor current flow through each of over 100 parts at a time, verifying enough current passed through the part for effective deburring and annunciating failures. To fit the monitoring system to the existing equipment, SIS was able to package the entire computer system, machine interface and data collection system in an enclosure just 14” by 16”.

Our solution led to a major cost savings for our client, eliminating the need for manual part inspection.